AMC Gremlin Barn Find and Restoration Story

Click the Gremlin thumnail to read the story.

Click the Gremlin thumnail to read the story.

Contact Us

For more information or questions on our products, click here.

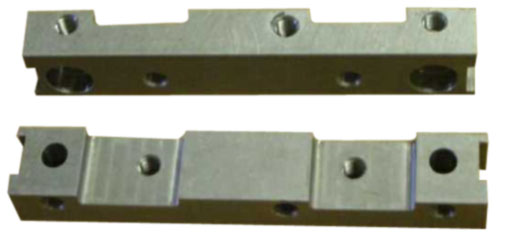

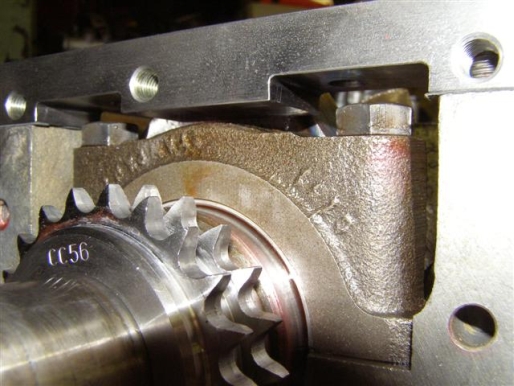

If you have an oil leak in the front of your TR6, GT6, TR250,Spitfire, or MG Midget with the Triumph 1500cc engine, it may be due to stripped threads in the sealing block/saddle bar or it could be warped. Classic Technologies is the originator of the re-engineered sealing block made from high-strength steel as shown in the pictures below. This part enables you to torque the bolts to the proper setting with plenty of margin if you overdo it.

If you’re going to be doing any lower-end work, we highly recommend you upgrade to this steel replacement part.

To learn more, google "TR6 Sealing block" and view the write-ups and comments on this part. Read what others have written and see the galleries of images documenting its installation.

The original TR6 sealing block has several serious design issues causing the threads to strip or the sealing block to warp. (See the right hole in the picture below).

The manual has a lower torque setting for these bolts because of this; but these bolts are on the bottom edge where the seal needs to be the best. Additionally, to have a good seal, the bolt torque around the gasket should be uniform.

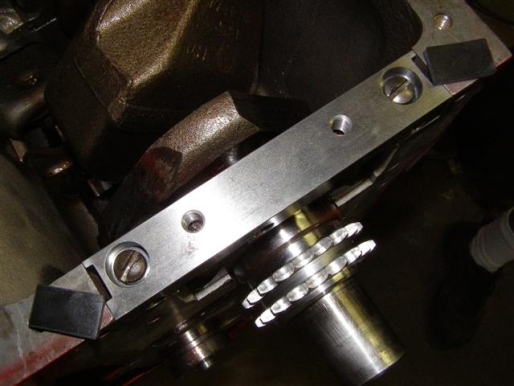

Here you can see the part installed. With 800+ sold to TR6 owners, Spitfire owners and GT6 owners, there has not been one dissatisfied customer or complaint that this part did not fit perfectly. If you're planning an engine rebuild or are tired of your oil leak, here is an integral part of the solution.

The engine does not need to be pulled out of the car to replace it. You may be able to just drop the oil pan and then carefully separate the front plate gasket from the sealing block, but for best results, the timing cover and front plate gaskets should be replaced as well.

Maybe you know ahead of time that the threads in your sealing block are bad. In this case, the decision to upgrade your sealing block shouldn't be too difficult. If you think your stock sealing block is ok, you may find out when its too late and are doing all your final torqueing (timing is set, RTV is on all the gaskets and engine assembly is 90+% complete). If one of those threads strip, you either live with the bad oil leak, or take a good part of the engine apart again, clean all the gasket faces again, order new gaskets and then order this steel replacement, getting delayed significantly. You could develop a leak sometime in the future, and would like to tighten the bolts a little more; chances are you will strip these threads with the stock sealing block, but not if you had the steel replacement. If you do strip a thread, then it is just that much more work to fix it. If you have the steel replacement, you will never have to worry about this part again.

To do the installation, you will need:

1. Oil pan gasket

2. Saddle bar/sealing block gasket set (comes with the gaskets for the bottom

of the sealing block and wooden wedges for the ends). We don't recommend the rubber replacements for the wooden wedges because they are too thick. The wooden wedges from the catalogs lately are very poorly made. Therefore, we are now supplying sealing blocks with properly sized wooden wedges.

3. Gasket sealer that you can find at any auto parts store.

Fuse Box

Fuse Box